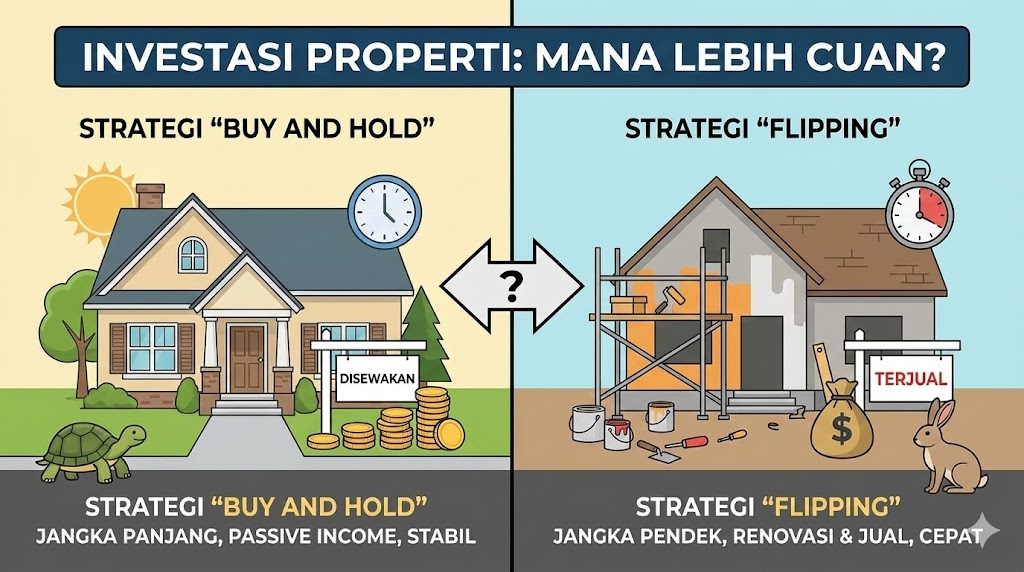

Strategi Investasi Properti: Buy & Hold vs Flipping, Mana Cuan?

Strategi “Buy and Hold” vs “Flipping”: Mana yang Lebih Cepat Cuan? edwardjonesrealestate – Pernahkah Anda…

Strategi “Buy and Hold” vs “Flipping”: Mana yang Lebih Cepat Cuan? edwardjonesrealestate – Pernahkah Anda menonton acara televisi yang menampilkan seseorang membeli rumah tua nan kumuh, merenovasinya hanya dalam sebulan, lalu menjualnya kembali dengan keuntungan ratusan juta? Terlihat sangat mudah dan menggoda, bukan? Di sisi lain, mungkin Anda memiliki paman atau bibi yang kerjanya hanya…

edwardjonesrealestate.com – When it comes to people with ADHD (Attention Deficit Hyperactivity Disorder), staying focused and engaged with activities can often be a challenge. Traditional hobbies that require sustained attention, like reading or even watching long movies, may feel overwhelming. So, it might come as a surprise to some that card games—known for their rules,…

Berikut adalah artikel KPR yang Anda minta: Mimpi Jadi Nyata: Panduan Lengkap KPR untuk Rumah Pertama Anda edwardjonesrealestate.com – Membeli rumah pertama adalah tonggak sejarah yang membahagiakan, namun juga bisa terasa menakutkan. Prosesnya yang kompleks, terutama dalam hal pembiayaan, seringkali membuat calon pembeli rumah pertama kebingungan. Salah satu cara paling umum untuk mewujudkan impian memiliki…

Menjelajahi Arsitektur Masa Kini: Dari Minimalis Elegan Hingga Canggihnya Smart Home edwardjonesrealestate.com – Di era yang serba cepat dan dinamis ini, hunian bukan lagi sekadar tempat berlindung. Ia telah bertransformasi menjadi representasi gaya hidup, nilai-nilai, dan bahkan visi masa depan. Tren hunian modern berkembang pesat, menawarkan beragam pilihan yang menyesuaikan dengan kebutuhan dan preferensi individu….

Berikut adalah contoh artikel yang bisa Anda gunakan: “`html Raih Kebebasan Finansial: Investasi Properti Komersial dengan Potensi ROI Ganda edwardjonesrealestate.com – Investasi properti selalu menjadi daya tarik, namun tahukah Anda bahwa investasi properti komersial menawarkan potensi **ROI (Return on Investment) ganda** dibandingkan properti residensial? Bayangkan memiliki ruko yang disewakan kepada minimarket atau kantor yang menghasilkan…

Berikut adalah artikel yang Anda minta: # Tren Properti Masa Kini: Transformasi Ruang Hunian di Tengah Gemuruh Kota Urbanisasi terus melaju kencang, mengubah lanskap kota dan cara kita hidup. Implikasinya terhadap pasar properti sangat signifikan. Di tengah gemuruh kota, ruang hunian bukan lagi sekadar tempat berteduh, melainkan cerminan gaya hidup, prioritas, dan bahkan nilai-nilai yang…

Berikut adalah artikelnya: Langkah Awal Menuju Sukses: Panduan Investasi Properti Rumah untuk Pemula edwardjonesrealestate.com – Investasi properti seringkali dianggap sebagai langkah besar yang hanya bisa diambil oleh mereka yang berpengalaman dan memiliki modal besar. Padahal, dengan perencanaan yang matang dan pengetahuan yang tepat, investasi properti hunian bisa menjadi gerbang menuju kebebasan finansial, bahkan bagi pemula…

Hunian Masa Depan: Investasi Properti Cerdas untuk Hari Esok edwardjonesrealestate.com – Memiliki properti impian bukan sekadar mimpi, tetapi sebuah langkah cerdas untuk merencanakan masa depan yang lebih aman dan sejahtera. Di tengah ketidakpastian ekonomi global dan perubahan iklim yang semakin terasa, investasi properti menawarkan stabilitas dan potensi pertumbuhan yang menjanjikan. Lebih dari sekadar tempat tinggal,…

Investasi Apartemen Kecil Strategis di Jakarta: Panduan Lengkap Investasi Apartemen Kecil Strategis di Jakarta: Pilihan Cerdas untuk Masa Depan edwardjonesrealestate.com – Di tengah hiruk-pikuk Ibu Kota, investasi apartemen kecil di Jakarta menawarkan peluang emas yang tak terbantahkan. Bagi Anda yang ingin memulai portofolio investasi properti atau mencari aset yang memberikan keuntungan jangka panjang, apartemen kecil…

Membidik Untung: Tren Investasi Properti Kota Metropolitan Terkini edwardjonesrealestate.com – Demam investasi properti di kota metropolitan tak pernah surut. Kenaikan harga tanah dan bangunan yang konsisten, ditambah dengan pertumbuhan ekonomi dan populasi perkotaan, membuat investasi properti menjadi pilihan yang menarik bagi banyak orang. Namun, navigasi pasar properti yang dinamis ini membutuhkan pemahaman yang mendalam tentang…